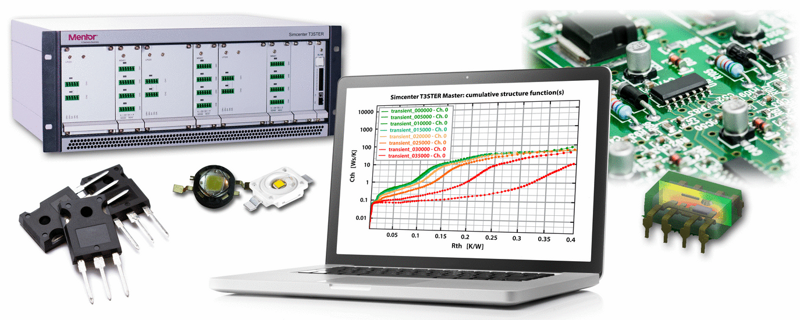

SIMCENTER T3STER

The Simcenter T3STER is aimed at testing integrated circuits using only electrical connections for power and sensing, providing fast and repeatable results that eliminate the need for multiple tests on the same component. Components can be tested in situ and test results can be used as a compact thermal model or to calibrate a detailed model.

Simcenter T3STER is easy to use and fast. It provides fully reproducible results, so each test only needs to be performed

once. Virtually all types of packaged semiconductors can be tested, from power diodes and transistors to large and highly

complex digital integrated circuits, including parts that are mounted on a board and even packaged in a product. Simply put,

a power pulse is injected into the component and its temperature response is recorded very accurately as a function of time.

The semiconductor itself is used both to power the component and to sense the temperature response using a temperature-sensitive

parameter on the surface of the die, such as a transistor or diode structure.

The software supplied with the Simcenter T3STER provides great value for this solution. That's because the Simcenter T3STER

software can take temperature versus time and use a series of complex mathematical operations to convert it into what's known

as a structure function. The structure function plots the cumulative thermal capacity that heat experiences as it passes through

the structure against the cumulative thermal resistance it must overcome. Discrete package features such as die fit can be

detected on this graph, making the Simcenter T3STER an excellent diagnostic tool in product development.

Proč Simcenter Simcenter T3ster?

- Simple and easy

- Fully reproducible

- Fast throughput

- A wide range of devices

- Non-destructive

- A look into the thermal structure

- Tests components on site

- Compact thermal models based on tests

- Detailed calibration of the thermal model

.png)

Are you even more interested in Simcenter T3ster? Write to us at info@techsim.cz

!