E-mobility

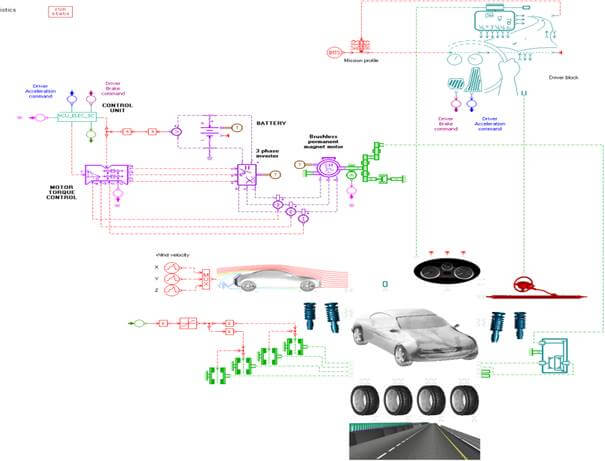

Electromobility is a new industry that has been booming over the past decade. Electrification of the drive does not only concern cars, but also motorcycles, buses, scooters and similar problems must be addressed, for example, for the electric drive of drones. The electric drive consists of an electric motor, control and power electronics (DC / AC converter, DC / DC converter) and power supply (battery pack, supercapacitors). The electric drive needs to be optimized in terms of power, range, cooling and other parameters to maximize performance and minimize cost. To do this, we use system simulations approach, where we implement the most realistic models of electric drive components. We also use this approach when it is necessary to find the best compromise among different electric drive concepts.

TechSim has a extensive experience in system simulation and electrical drive design. We offer the following types of analyzes:

| Analysis type | Description |

|---|---|

| Driving ranges | Determination of the appropriate driving range for a given duty cycle (WLTP, NEDC, etc.) |

| Drive dimensioning | Determination of optimal parameters of electric motor, power electronics and battery pack for a given duty cycle |

| Design and optimization of electric motor | Electromagnetic design of electric motor and its optimization |

| Thermal calculations | Analysis of thermal load of various parts of electric motor, power electronics or battery pack during a given duty cycle, determination of cooling requirements of individual components |

| Power electronics model (DC / DC, DC / AC converters) | Calculation of power electronics losses |

| Clima comfort | Energy performance model of clima comfort and its influence on driving range |

| Drive control | Optimization of electric or hybrid drive control strategy with respect to overall efficiency or emissions |

The electric vehicle battery is currently the most expensive part of the drive. The cells differ from each other in the density of stored energy, maximum currents, operating temperature range, losses and service life. To avoid aging, ensure a homogeneous temperature across the battery pack and avoid local overheating of the battery cells under increased load or charging. In this area TechSim offers the following types of analyzes:

| Analysis type | Description | Software |

|---|---|---|

| Battery Simulation | Virtual design and testing of battery cells | |

| Battery pack cooling | Analysis of homogeneity of battery pack cooling, hot-spot prediction | Simcenter Battery Design Studio, Simcenter STAR CCM+ |

| Comparison battery cells / battery packs | Based on the measured data or datasheet, we will create a model of the cell / battery pack and compare cells with each other or different battery pack topologies and evaluate their suitability for the given application. | Simcenter Amesim |

![[battery(1).png]](https://www.techsim.cz/content/images/battery(1).png)